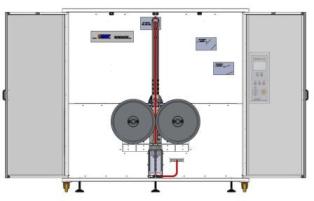

The cable sample must be bent forwards and backwards with angles of up to 270° with the two extreme positions forming a 135° angle on both sides of the vertical section while the sample is subjected to traction.

The equipment can be used for tests only on cables and on cables with connectors.

It is capable of performing two types of cycles:

The parameters that characterise the test include: bending speed and angle, radius of the bend, number of cycles and traction load.

The cable must resist for a defined number of bending cycles without damage (interruption) under the stated conditions.

SIF, through its collaboration with the most important testing and research institutes, comparing notes with customers and scrupulous analysis of normative requirements, has been able to develop a product that focuses primarily on:

The true value added of the equipment consists of the innovative solutions created through the inventiveness of our Research & Development Team, which has succeeded in uniting creativity and engineering to: